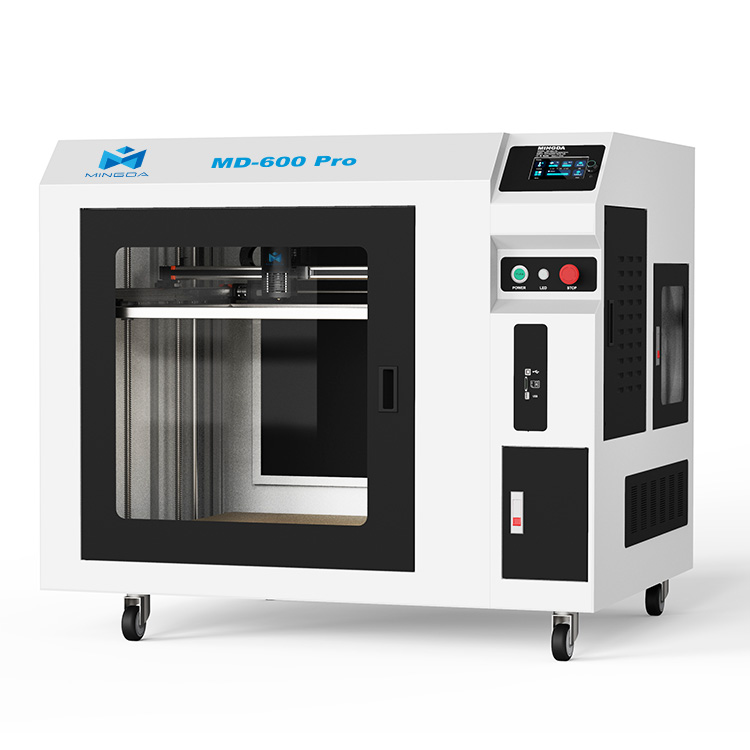

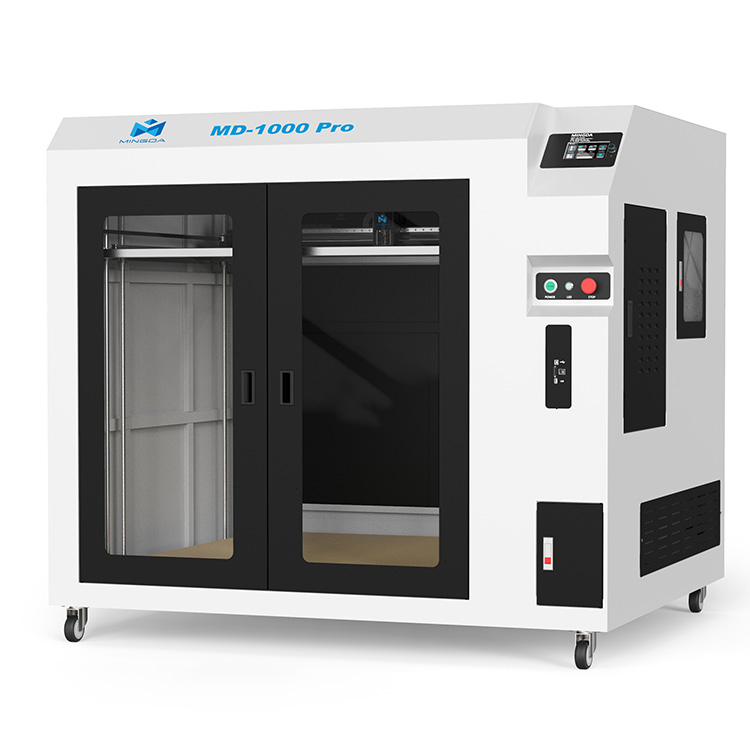

Premium Efficiency For Industrial 3D Printing

The MD-600 Pro is an easy-to-use, large-format 3D printer specially designed for industrial applications using engineering-grade materials. With a sleek, space-conscious body, perfect for the production of quality parts in any setting, the MD-600 Pro is optimal for any workspace, from the office to the factory floor. Whether it's factory tooling, prototypes, or end-use parts, the MD-600 Pro is a durable and cost-effective way to manufacture large-format, quality parts.

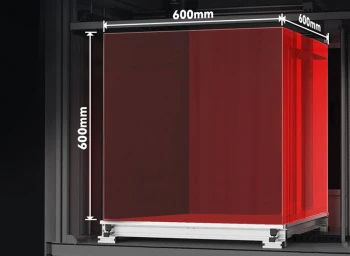

The MD-600 Pro boasts a generous build volume of 600 * 600 * 600 mm, 10 times that of standard desktop 3D printers. Featuring a fully enclosed build envelope and temperature-controlled filament chamber, the fast-heating MD-600 Pro produces incredible results with advanced materials.

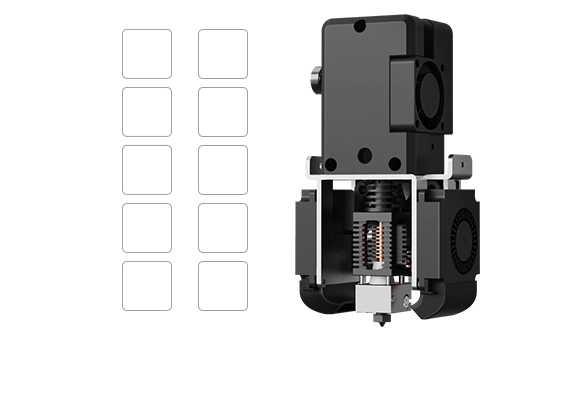

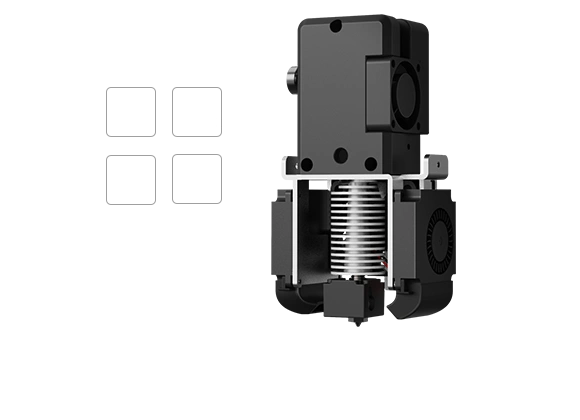

Two Nozzle Modes To Meet Different Material Requirements

The MD-600 Pro is a high-performance and commercial industrial 3d printer. It can be equipped with a high-temperature hot end or standard-temperature hot end, which can swap quickly for different applications or filaments.

Massive Build Volume

MD-600 Pro has massive build volume of 600*600*600(mm) which enable engineers and makers to print parts in single piece.

Accurate Linear Guide Rail

Large-scale printed models the appearance of 4 to 5 times more precision than ordinary 3D printing

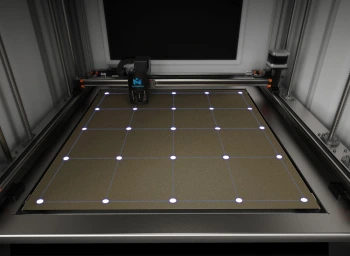

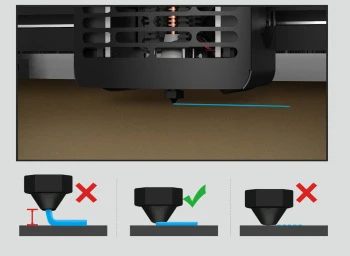

Innovator Of Industrial 3D Printer Auto-Leveling

The interlligent leveling system can automatically adjust the uneven hotbed. High-sensitivity sensor, one-touch leveling and 25-point precise leveling.

Baby Step Intelligent Compensation

Baby step function is added on MD-600 Pro During the first layer printing process, the baby step can be used for precise leveling. The control accuracy of 0.01mm makes the first layer stable and reliable and makes the leveling more intelligent.

UPS (Uninterrupted Power Supply)

Buit in UPS, When the machine is powered off, the machine will automatically suspend printing, and retum to the home point, when the power on, the machine will continue to complete the remaining printing work from the point of suspension.

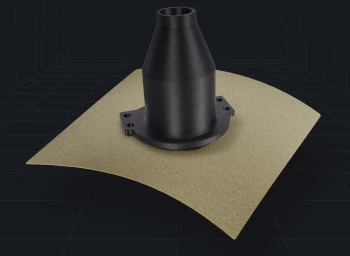

Maximum Adheshion Painless Removal

Our Build Plate system completely removes scrapers and damage to 3d prints. The magnetic build plates that come with MD-600 Pro are flexible and detachable so you can remove the models with ease.

Product Parameters

| PRINTING | |

|---|---|

| Printing Technology | Fused Deposition Modeling |

| Bulid Volume | 600*600*600mm |

| Number of Nozzle | Single |

| Layer Thickness | 0.05-0.3mm |

| Filament Diameter | 1.75mm |

| Filament Campatibility | PLA、ABS、ASA、TPU、PETG、PETG-ESD,PET-GF, PET-CF, PA12-CF,HtPA-GF, HtPA-CF |

| Nozzle Diameter | 0.6mm (0.4mm, 0.8mm optional) |

| ELECTRICAL | |

|---|---|

| Power Requirements | 110/220V |

| Rated Power | 1200w |

| Screen | |

| Connectivity | USB, SD card, U disk |

| SPECIAL FUNCTION | |

|---|---|

| Uninterruptible Power System | Save data when power is off |

| Resume Printing After Power Failure | Available |

| Filament Detection | Pause printing when filament run out |

| Automatic Shutdown | Turn off the power automatically when printing is complete |

| TEMPERATURE | |

|---|---|

| Max. Nozzle Temp. | 350degree |

| Max. Bed Temp. | 110degree |

| SPEED | |

|---|---|

| Recommend Printing Speed | 60-100mm/s |

| Max Printing Speed | 200mm/s |

| MECHANICAL | |

|---|---|

| Construction | Power-coated Steel, Aluminum Casting for Motion Components |

| Platform | 10mm thickness aluminum hot bed |

| Leveling | auto-leveling |

| X Y Postition Precision | 0.015mm |

| Z Postition Precision | 0.0015625mm |

| SOFTWARE | |

|---|---|

| Support Software | MCura, Reptier-Host, Simplify3D |

| Supported File Types | Stl, Obj, G-code |

| Operating Systems | Windows(7,8,10),Mac OS X |

Have Questions about MINGDA 3D PRINTER Offers?

We can help you determine the best option for your team.

CALL +62 (21) 315 6626